1. Achievement of a new type of steel manufactured by adding ceramic nanoparticles to a microalloyed steel in a liquid state prior to its casting process. Development of a feasible addition technique to disperse the nanoparticles.

2. Continuation of the industrial transfer of steels with carbide-free nanobainitic microstructures. These steels present an unprecedented combination of strength and ductility and, in addition, we have recently obtained very promising results in terms of fatigue resistance.

3. Creation of a methodology to predict the performance of stainless steels as a function of their forming and finishing treatments. Development of constitutive models and an in-depth characterization of the material after the applied processing.

4. Development of a new generation of AHSS steels with an excellent combination of strength, toughness, ductility and formability by means of grain refinement and nanoscale precipitation at the transformation interface.

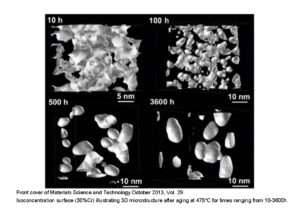

5. Pursuit of the feasibility of producing globular ferrite and cementite microstructures directly during intercritical rolling without any subsequent heat treatment.

6. Search for an alternative to the alloys hardened by dispersion of nanometric oxides (ODS alloy) to achieve ferrous alloys resistant to high temperature. A uniform dispersion of ceramic particles will be sought by means of tools such as alloy design and the optimization of controlled thermomechanical processing (TCMP), to achieve an alloy with properties equivalent to ODS alloys.

It should be noted that these lines are perfectly framed within the priorities set by the EU as part of the Horizon 2020 plan, and the document "Metallurgy Europe - A renaissance programme for 2012-22", generated by more than 100 experts gathered in the Materials Science and Engineering Expert Committee (MatSEEC) and commissioned by the European Science Foundation (ESF).